Thermal Transfer Printing: An Introduction to the Basics

In a world where labels, receipts, and barcodes are essential for tracking and identifying goods, thermal transfer printing has emerged as a reliable solution within the coding and marking industry. This technology is revered for its durability and versatility, making it an ideal choice for many businesses.

If you’re thinking of investing in a thermal transfer printer, then you probably want to know how it works and the type of results you can expect to see from it. Luckily, this blog provides you with an introduction to the basics.

What is Thermal Transfer Printing?

Thermal Transfer Printing is a digital printing method that utilises heat to transfer ink from a ribbon onto a variety of materials such as paper, plastic, or fabric to create a permanent image.

How does it work?

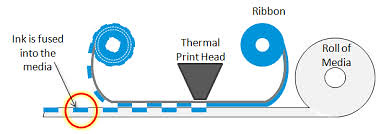

Delving into the world of thermal transfer printing reveals a fascinating interplay of components that work together in unison to produce crisp and durable images. At the heart of this technology lie three core elements: the thermal printhead, the ribbon, and the substrate.

The Thermal Printhead

The heart of the system, the thermal printhead comprises tiny heating elements that activate the transfer process.

The Ribbon

Acting as an intermediary, the ribbon carries the wax or resin material that gets transferred onto the substrate.

The Substrate

The material onto which the image or text is printed, commonly being paper, plastic, or even fabric.

Cooling and Solidifying

Once transferred, the material from the ribbon cools and solidifies quickly, leaving behind a permanent, high-quality image or text.

The technology works by melting a wax or resin substance on a ribbon and transferring it onto a medium to create a precise, long-lasting image. This process is carried out by a thermal printhead that heats up the ribbon at varying temperatures, enabling the transfer of the material onto the substrate.

Each component has a distinct role, yet they collaborate seamlessly in order to transfer images or text from the ribbon onto the substrate, ensuring a high-quality print. Understanding the mechanics and functions of these key components is crucial for anyone looking to invest in this type of technology.

Understanding Thermal Transfer Ribbon

If you’re thinking of investing in a thermal transfer printer, then you need to familiarise yourself with thermal transfer ribbon. It is a critical component in the thermal transfer printing process and finding the right one requires some consideration.

The ribbon consists of a polyester film that is coated on one side with a wax, resin, or a mixture of both. As the ribbon makes contact with the heated printhead, the coating melts and transfers onto the substrate to form the desired image or text.

The type of coating selected – wax, resin, or a mixture of both, significantly impacts the durability and the quality of the print. Wax-based ribbons are great for general-purpose printing, providing a smudge-free and clear output on smooth surfaces.

On the other hand, resin-based ribbons offer superior resistance to chemicals, heat, and abrasion, making them ideal for harsher environments. A mixture of wax and resin provides a middle ground, offering better durability than wax alone, and is often chosen for printing on glossy paper or synthetic materials.

Selecting the right thermal transfer ribbon is pivotal for achieving the desired print quality and durability, making it an essential consideration for businesses employing thermal transfer printing technology.

Advantages of Thermal Transfer Printing

In the modern industrial landscape, creating legible and lasting prints is crucial for efficient operations and accurate tracking. Thermal Transfer Printing has emerged as a go-to technology for businesses looking to achieve high-quality prints with a lasting impact.

Unlike its counterpart, direct thermal printing, thermal transfer printing utilises a ribbon to transfer images or text onto a variety of substrates, this ensures both durability and clarity.

This printing method is not just versatile in the kind of materials it can print on, but also boasts of a high-resolution output which is pivotal in applications where precision is a non-negotiable factor.

Check out why it has become an indispensable tool in modern-day labelling and coding.

High Durability

Unlike other printing technologies, thermal transfer printing produces durable prints that can withstand harsh environments, making it suitable for outdoor applications and industrial settings.

Versatility

The ability to print on different materials makes thermal transfer printing a versatile choice. Whether it’s labels for products, barcodes for tracking, or receipts for transactions, the applications are extensive.

High Resolution

Known for its high-resolution output, thermal transfer printing is ideal for creating fine details and small text. This is crucial for applications like barcode printing where accuracy is paramount.

Long-lasting Prints

The prints created are resistant to fading and remain eligible for many years, making it a preferred choice for archival purposes.

Applications of Thermal Transfer Printing

Thermal transfer printing finds its applications across various sectors including retail, healthcare, manufacturing, and transportation. It is essential for creating labels for products, shipping labels, asset tagging, generating receipts and industrial settings for product tracking.

With a balance of durability, versatility, and high-quality output, thermal transfer printing is a vital asset for organisations looking to streamline their labelling and tracking processes. By understanding the basics and the components involved in thermal transfer printing, businesses can make informed decisions to cater to their specific needs.

Is It Right For Your Operation?

Determining whether thermal transfer printing is the right fit for your operation hinges on your specific needs. If your enterprise demands high-resolution, durable prints that can withstand the test of time and environmental challenges, thermal transfer printing emerges as a compelling choice.

Furthermore, its versatility in printing on various materials enhances its appeal, providing a robust solution for a myriad of printing applications.

Investing in thermal transfer printing technology could significantly streamline your operational processes, improve the accuracy of tracking and identification, and ultimately contribute to optimising the overall efficiency and productivity of your business.

By thoroughly evaluating your printing requirements and the environment in which the prints will be utilised, you can make an informed decision that propels your operation towards enhanced efficacy and reliability.

Get in touch with us at Obeeco to discuss thermal printing technology for your business.