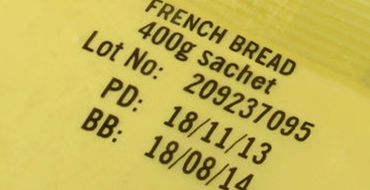

A coding machine should meet the needs of your operation and keep pace with your production line. Before investing in a coding machine, be sure to consider the following:

The type of material you’re marking can dictate the best coding method. For instance, laser coders might be ideal for glass or certain plastics, while an inkjet coding machine might be better for cardboard.

High-speed production lines might require faster coding methods like CIJ or laser coding, whereas, in small-scale operations, a hot foil printer may be a more suitable option.

In environments where the product might be exposed to moisture, chemicals, or friction, a more permanent coding machine method might be necessary.

Consider your initial coding machine investment and the ongoing costs (like ink or label refills) which can vary significantly between machine types. Be sure to select a coding machine that you can afford to keep running.

Some machines might require more frequent maintenance or cleaning. Be sure to do your research beforehand and understand the requirements for ensuring optimal machine performance.

It’s also worth keeping in mind that you may want to choose a coding machine that can keep pace as your operation grows. If you are expecting to add more products or expand your product base, it may be worth investing in a high-performing coding machine that can cope with that increased demand.